Potato Starch Processing

Tidecom Group adheres to the business philosophy of "creating value for customers and innovating life with technology", integrates global industry resources, continues technological research and development innovation, and is guided by market customer needs, providing customers with more cost-effective products and services.

Potato starch is a valuable and promising starch resource, characterized by its exceptional physical and chemical properties as well as cost-effective advantages. The market application of potato starch is becoming increasingly extensive, with a rapidly growing demand year after year. In the field of Potato starch processing, TTC Group has successfully delivered so many potato starch turn-key projects and complete production lines to customers worldwide. Additionally, we have supplied numerous key equipment for potato starch production. Tailoring our solutions to meet the specific requirements of customers in different countries and regions, we consider local raw material availability and product market demands. Our services includes plant site investigation, engineering design, equipment manufacturing & supply, equipment installation & commissioning, staff training and after-sales service. We are committed to ensuring the success of our customers' projects while striving to create value through our business services.

Category:

Keyword:

Special equipment | General purpose

Product Description

Potato starch is a valuable and promising starch resource, characterized by its exceptional physical and chemical properties as well as cost-effective advantages. The market application of potato starch is becoming increasingly extensive, with a rapidly growing demand year after year. In the field of Potato starch processing, TTC Group has successfully delivered so many potato starch turn-key projects and complete production lines to customers worldwide. Additionally, we have supplied numerous key equipment for potato starch production. Tailoring our solutions to meet the specific requirements of customers in different countries and regions, we consider local raw material availability and product market demands. Our services includes plant site investigation, engineering design, equipment manufacturing & supply, equipment installation & commissioning, staff training and after-sales service. We are committed to ensuring the success of our customers' projects while striving to create value through our business services.

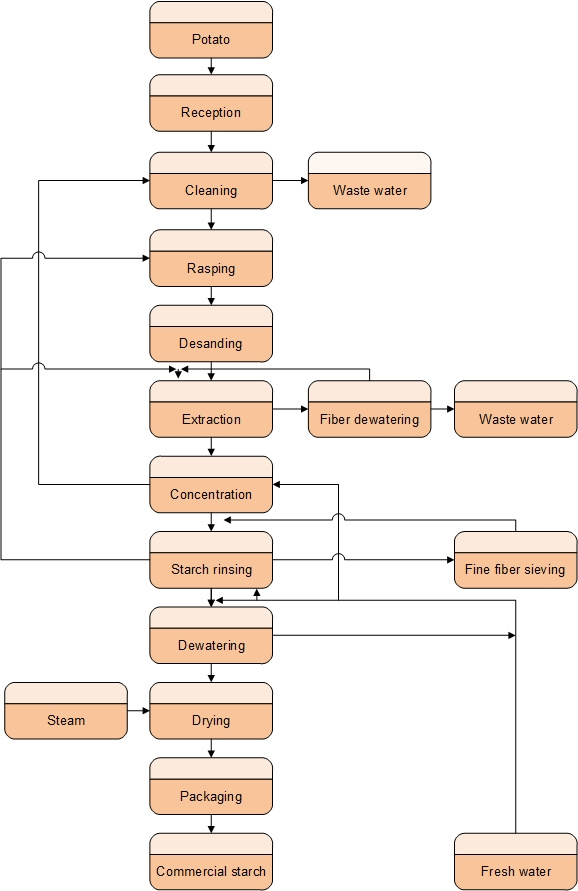

Process Flow Of Potato Starch

Process Flow Of Potato Starch

● Cleaning & Washing

Using cleaner,destoner or drum washer to clean raw material completely.

● Rasping & Desanding

Clean Potato is slurred by rasper which almost all starch granules are released. Fine sand or other impurities are separated by desanding device.

● Centrasieving

Potato slurry treated by centrasieves and removed almost all fibers.

● Hydrocyclone Refining

Crude starch is refined by hydrocyclone unit to separate protein, fine fiber, salt and etc.

Crude starch is refined by hydrocyclone unit to separate protein, fine fiber, salt and etc.

● Starch Milk Dewatering

Most part of moisture in starch milk is removed by centrifugal peeler or vacuum filter.

● Drying & Cooling

Wet starch cake is dried by flash dryer and cooled by air, to reach the moisture content of commercial starch.

● Sifting & Storing

Dried starch is sifted and reached to standard of fineness, and stored in silo.

● Weighing & Packing

Fully automatic or semi-automatic packing machine is used, by jumbo bag or 25/50 Kilo bag.

Process target

● Higher extraction yield

The comprehensive extraction rate of starch reaches over 95%.

● Better product quality

Ensure that all products are of superior quality when the raw materials are fresh.

● Lower energy consumption

A lots of practical applications have verified that the production water consumption, electricity consumption and heat consumption have reached a minimum level.

● Easier operation

The user-friendly automatic control system makes the production operation much easier.

System advantages

● By adopting a complete set of the most advanced and mature European process technologies, combined with domestically manufactured equipment according to European standards, the production system can achieve the highest cost-effectiveness;

● Fully enclosed and modular structure, compact layout and greatly reduce equipment installation time;

● The control system is stable and reliable, and can provide various control systems from fully automatic to manual according to customer requirements;

● We have adopted the latest 3D design system to provide customers with more detailed drawing materials, which facilitates installation and saves time.

Related Products

Online Message