Potato Protein Processing

Tidecom Group adheres to the business philosophy of "creating value for customers and innovating life with technology", integrates global industry resources, continues technological research and development innovation, and is guided by market customer needs, providing customers with more cost-effective products and services.

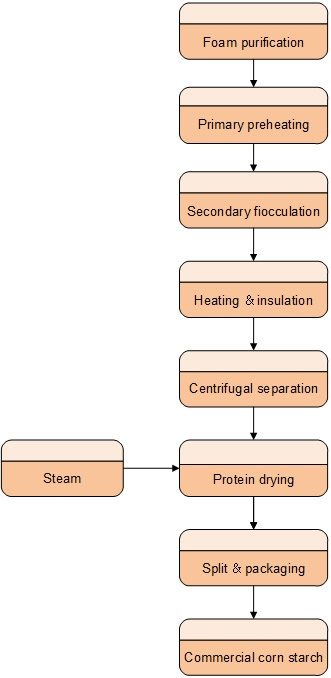

Potato protein is produced from the juice after starch extraction, which goes through various operational procedures such as cyclone impurity removal, defoaming purification, plate exchange preheating, heating flocculation, centrifugal separation, drying and packaging. The entire processing process does not add any additives, producing pure natural and pollution-free commodity potato protein powder, which is a high-quality raw material of feed protein for young livestock.As a byproduct of potato starch processing, potato protein has good functionality, high essential amino acid content, rich nutritional value, and can reduce the pollution caused by potato starch processing wastewater (juice), expanding the comprehensive development and utilization of potatoes.

Category:

Keyword:

Special equipment | General purpose

Product Description

Process flow

(1) Hydrocyclone impurity removal:

Use hydrocyclone to further remove impurities from the diluted cell fluid, avoiding small starch particles from entering the protein extraction system.

(2) Defoaming purification:

The diluted cell fluid that has undergone cyclone purification contains bubbles, which require defoaming treatment in a defoaming tank to minimize the gas content in the juice and discharge the precipitated starch.

(3) Multi stage heating:

The material liquid preheated by the first stage spiral flocculator enters the second stage spiral flocculator for further heating and warming.

(4) Thermal insulation flocculation:

The material liquid heated by a two-stage spiral flocculator is injected with steam by a steam heater into the material liquid, and the steam is completely mixed with the material liquid.

(5) The heated and flocculated feed liquid enters the horizontal spiral centrifuge through a heat exchanger and pipeline for solid-liquid separation.

(6) The protein separated by a horizontal spiral centrifuge enters the protein drying unit through a horizontal and inclined screw conveyor set at the bottom.

(7) The dried protein enters the packing silo, is sifted and packed according to customer needs, and is sent to the warehouse for storage.Due to the low moisture content of the dried protein, it can be stored for long periods of time and transported over long distances.

Related Products

Online Message