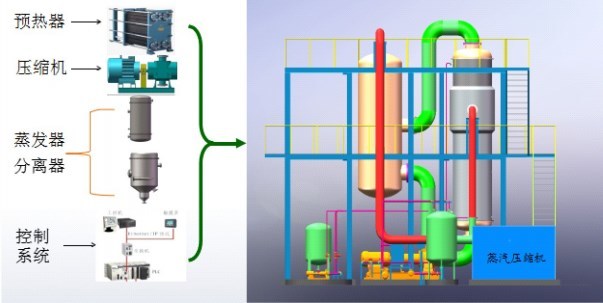

MVR Evaporation System

Tidecom Group adheres to the business philosophy of "creating value for customers and innovating life with technology", integrates global industry resources, continues technological research and development innovation, and is guided by market customer needs, providing customers with more cost-effective products and services.

MVR (Mechanical Vapor Recompression) refers to the process of compressing the secondary steam from evaporation, distillation, and other processes again with a compressor, increasing the enthalpy of the compressed secondary steam, and reheating the materials that need to be evaporated as a heat source, thereby achieving the goal of recycling steam and eliminating the need for additional steam supplementation during the evaporation process; A high-efficiency energy recycling and energy-saving evaporation technology that uses a small amount of electrical energy to obtain more thermal energy, thereby reducing the system's demand for external energy.

Category:

Keyword:

Special equipment | General purpose

Product Description

MVR system composition: preheater, evaporator body, separator, compressor, pump, valve instrument, automatic control system, steel platform, etc.

Advantages of MVR evaporator:

1. The evaporation temperature is low and can be controlled at a minimum of 45-55 ° C, with no foaming, no material leakage, and high evaporation efficiency.

2. The heat exchange temperature difference is small, which can achieve mild evaporation and is not prone to coking, making it very suitable for heat sensitive materials.

3. It can be used to evaporate materials with high concentration and high viscosity (0.05-0.45Pa * s), with membrane flow and small temperature difference loss.

4. The structural process is simple, can run continuously, and is safe and reliable.

5. The equipment is equipped with CIP fully automatic cleaning pipelines, and the workmanship is precise, completely achieving no residue or dead corners.

6. It does not require a steam condenser, has a simple structure, is easy to maintain, and can be operated under reduced pressure, normal pressure, and pressurized conditions.

Performance Comparison:

| Item/Type | Reaction kettle | Single effect evaporator | Multiple effect evaporator | MVR evaporator |

| Energy consumption | Evaporating one ton of water requires about 1.5-2 tons of fresh steam | Evaporating one ton of water requires about one ton of fresh steam | The five effect evaporator requires about 0.3 tons of fresh steam to evaporate one ton of water | Evaporating one ton of water requires about 35-70kw/h of electricity consumption |

| Energy source | Fresh steam | Fresh steam | Fresh steam | Industrial electricity |

| Operating cost | Extremely high | Higher | High | Low |

| Product quality | The product has a long residence time and unstable quality, which has a significant impact on the product quality. | Short product dwell time, large temperature difference, and minimal impact on product quality. | The product has a long residence time and a large temperature difference, which has a small impact on product quality. | Short product retention time, low-temperature evaporation, and minimal impact on product quality. |

| Control mode | Manual | Semi-automatic | Semi-automatic | Fully automatic |

| Cover an area | Small | Small | Large | Small |

Related Products

Online Message