Lotus Starch Processing

Tidecom Group adheres to the business philosophy of "creating value for customers and innovating life with technology", integrates global industry resources, continues technological research and development innovation, and is guided by market customer needs, providing customers with more cost-effective products and services.

Lotus starch is a traditional food well known for its nutritious value and medical use. If it is made into the instant food, people could handle it in 1 minute.

Category:

Keyword:

Special equipment | General purpose

Product Description

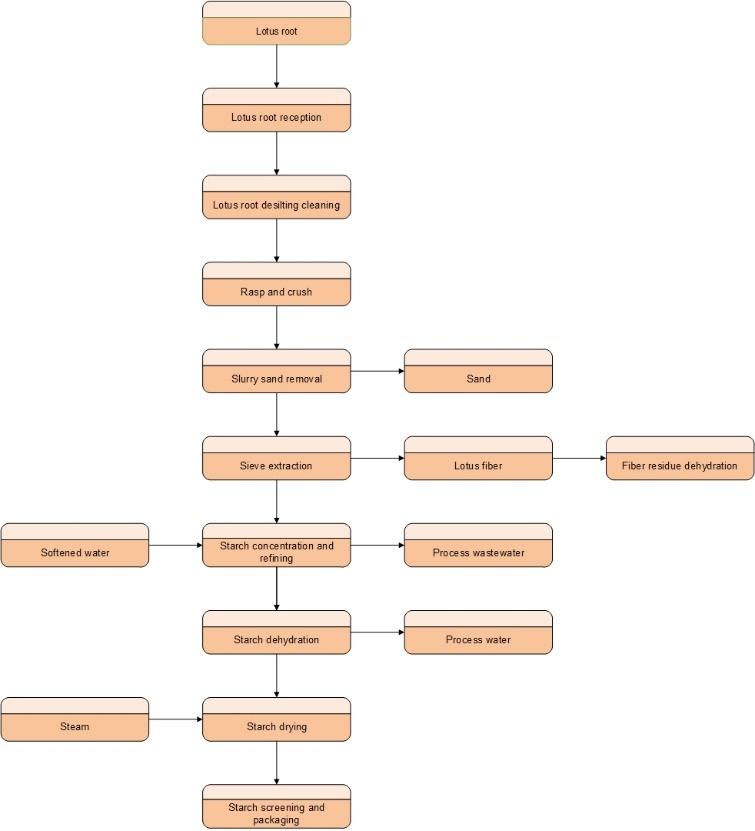

Process flow

There are two methods for lotus starch production:

traditional handmade production methods and modern technical production methods. The traditional handmade production process relies entirely on hand made: low processing efficiency, poor production health environment and product quality is not high. The modernized processing technology could effectively solve the problems of the traditional process. The modernized production process of lotus root starch offered by TTC Group includes: lotus root - cleaning - filing and crushing - desanding - centrifugal sieving - concentrating and refining - dewatering - drying - sieving and storage - packaging.

Cleaning& Washing:

Using destoner, paddle washier or drum washer to completely make cleaning of raw material.

Rasping&Chopping:

The cleaned lotus root is fully crushed by the filing mill to release more free starch granules and ensure higher starch extraction rate.

Desanding:

A specially designed grit remover is placed after the desanding device to efficiently separate sand and other impurities, reducing the ash content of the product while protecting the centrifugal sieve to ensure higher quality.

Centrasieving:

According to different situations, choose different specifications of centrifugal sieve with, so that the fiber and starch in the lotus root slurry is fully separated, while reducing the starch loss.

Hydrocyclone Refining:

This is the most important unit of the whole lotus root starch production line that affects the quality and quality of starch. Multi-stage pre-dewatering cyclone station and multi-stage high-efficiency de-watering and refining cyclone station are adopted to ensure the effective separation of protein and fine fiber.

Dewatering:

Adopting vacuum filter to ensure uniform and stable moisture content of dewatered materials and lower water content, saving energy consumption in drying process.

Drying& Cooling :

Utilizing the high-speed flow of hot air in the airflow dryer to suspend the wet starch therein, the dehydrated starch is further dried to the moisture content required for commercial starch during the airflow process.

Sifting& Storing:

Dried starch is sifted and reached to standard of fineness, and stored in silo.

Weighing & Packing :

Fully automatic or semi-automatic packing machine is used, by jumbo bag or 25 Kilo bag.

Related Products

Online Message