Fluidized Bed Drying Technology

Tidecom Group adheres to the business philosophy of "creating value for customers and innovating life with technology", integrates global industry resources, continues technological research and development innovation, and is guided by market customer needs, providing customers with more cost-effective products and services.

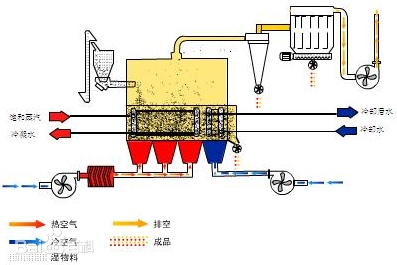

Fluidized bed drying technology is a new type of drying technology that has developed in recent years. The process involves placing bulk materials on an orifice plate and conveying gas from its lower part, causing material particles to move on the gas distribution plate and remain suspended in the airflow, producing a mixed bottom layer of material particles and gas, similar to liquid boiling.In the fluidized bed dryer, the material particles come into full contact with the gas in this mixed bottom layer, conducting heat and water transfer between the materials and the gas.

Category:

Keyword:

Special equipment | General purpose

Product Description

Fluidized bed drying technology is a new type of drying technology that has developed in recent years. The process involves placing bulk materials on an orifice plate and conveying gas from its lower part, causing material particles to move on the gas distribution plate and remain suspended in the airflow, producing a mixed bottom layer of material particles and gas, similar to liquid boiling.In the fluidized bed dryer, the material particles come into full contact with the gas in this mixed bottom layer, conducting heat and water transfer between the materials and the gas.

The characteristics and application of fluidized bed drying

Fluidized bed drying has the advantages of high heat and mass transfer rates, high drying rate, high thermal efficiency, compact structure, low basic investment and maintenance costs, and easy operation.Therefore, fluidized bed dryers are widely used in industries such as chemical, food, ceramics, pharmaceuticals, polymers, etc.

Related Products

Online Message