Recent Information

News

Dear users, welcome to read the latest news of our company. In this report, we will introduce you the latest information about our company.

Contact +

Quality Witnessed! South American Clients Conduct On-Site Inspection at Tidecom Group!

Release time:

2025-07-25

In the vast landscape of the global market, Tidecom Group has consistently earned the trust and support of numerous clients through its exceptional product quality and professional services. Recently, the Group welcomed distinguished guests—South American clients—who personally visited Tidecom's production facilities to conduct rigorous inspections of upcoming deliveries. This was not merely a routine quality check, but a powerful demonstration of Tidecom's unwavering commitment to excellence.

1.Fully Prepared for Customer Inspection

In preparation for the visit from South American clients, Tidecom Group mobilized all departments with utmost attention. Every detail was meticulously arranged—from workshop preparation to final product testing—demonstrating the company's firm belief that customer trust is built upon flawless execution at every stage.

The production team conducted comprehensive equipment cleaning and maintenance to ensure optimal operational conditions. All machine parameters were double-checked to guarantee product consistency, while technicians performed multiple self-inspections. From raw material selection to production processes and final packaging, each step strictly adhered to both international standards and the clients' specific requirements, reflecting Tidecom's uncompromising commitment to quality excellence.

2. Showcasing Strength: Powered by Six Core Technologies

Tidecom Group has distinguished itself in the global market through its robust technological capabilities. During discussions with South American clients, the Group provided a comprehensive overview of its "Six Core Engineering Technologies."

In project engineering design, Tidecom strictly complies with international standards while thoroughly considering client requirements and on-site conditions to deliver well-structured and practical engineering solutions. A prime example is the Tianshan Snow 100-ton Production Line Project, where Tidecom's exceptional engineering design ensured smooth project commissioning.

Process R&D and design represent another area of Tidecom's expertise. The company develops tailored processes and equipment based on specific client needs. For instance, during a major project in Vietnam, when the client demanded starch purity levels exceeding national premium-grade standards, Tidecom's R&D team promptly conducted technical research, optimized the production process, and successfully met the client's elevated expectations. Additionally, in starch recovery technology, Tidecom developed an advanced hydrocyclone system matching European technological standards, significantly improving starch concentration efficiency while reducing operational costs. Furthermore, its innovative cassava peeling machine for cassava flour production effectively addressed longstanding industry challenges.

Tidecom has achieved remarkable breakthroughs in hydrocyclone separation technology, having mastered precise material balance calculations to ensure optimal system performance. Through continuous optimization of operational parameters and supporting equipment, we successfully enhance production capacity while reducing energy consumption, thereby creating greater value for our clients.

Our high-efficiency, energy-saving drying technology represents another technological highlight. The specially designed airflow dryer reduces thermal energy consumption by 30%, demonstrating Tidecom's outstanding technical advantages in energy conservation and environmental protection.

The company's automated control systems are renowned throughout the industry for their numerous control points, real-time monitoring capabilities, and advanced warning functions. The Tianshan Snow Project, featuring over 4,000 control points, has become an industry benchmark, providing robust quality assurance.

In comprehensive utilization technology, Tidecom champions the "total input-total output" deep processing concept. This innovative approach fully extracts all valuable components from tuber crops, processing them into starch, dietary fiber, protein, and liquid organic fertilizer. This achieves zero-emission starch production while significantly improving resource utilization efficiency and economic benefits, showcasing Tidecom's commitment to sustainable development.

3. Superior Quality Earns Customer Praise

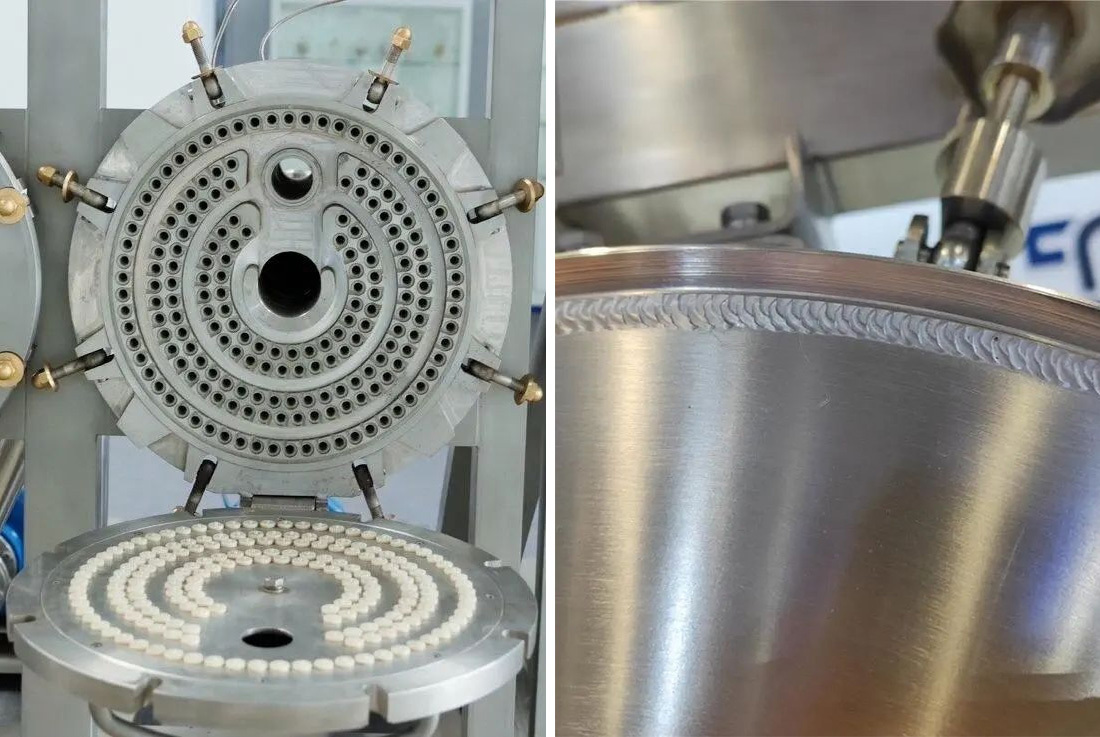

During the inspection, the South American client conducted a meticulous examination of Tidecom Group's products. From exterior dimensions and manufacturing craftsmanship to internal structure and performance parameters, every aspect was rigorously evaluated against their quality standards. Thanks to their exceptional quality, Tidecom’s products successfully passed all inspection criteria.

The client spoke highly of Tidecom Group’s product quality, praising the products not only for meeting their stringent requirements but also exceeding expectations in fine details. This not only reflects Tidecom’s rigorous commitment to quality control but also demonstrates its strong competitiveness in the global market.

This on-site product inspection by our South American client marks a new milestone in Tidecom Group's quality journey. Going forward, Tidecom Group will remain committed to the principle of "Quality First, Customer Supremacy," continuously enhancing product quality and service excellence. With premium products and tailored solutions, we strive to meet the demands of global customers and achieve even greater success in the international market.

Related news