Recent Information

News

Dear users, welcome to read the latest news of our company. In this report, we will introduce you the latest information about our company.

Contact +

Tianshanxue's 100 ton/hour potato starch production line has successfully operated

Release time:

2024-10-20

September 10, 2024 is a memorable day for Xinjiang Tianshanxue Co.,Ltd. (referred to as "Tianshanxue"), as it marks the successful operation of the first 100 ton/hour potato starch production line in the domestic potato starch industry.

As of today, the line has been in operation for more than 30 days without any downtime. Li Wei, vice president of Tianshanxue in charge of production, said: "The equipment is running very stably, with zero failure rate. The product quality is also very stable, producing about 400 tons of refined starch every day, with a starch whiteness of more than 93, a viscosity of more than 1600BU, and a high-quality rate of more than 99%."

Hu Dong, Chairman of Anhui Tidecom Technology Group, a manufacturer of the 100 ton/hour large-scale production lines, said that this line embodies Tidecom's most advanced technology in potato starch production line, mainly reflected in five aspects:

firstly, as the largest single line production line in China and even internationally, the Tianshanxue 100 ton/hour potato starch production line, engineering design is one of the key factors for the success of the project. During the implementation of the Tianshanxue Project, Tidecom's engineering and technical personnel were guided by customer needs and combined with the actual project site to provide standardized and reasonable engineering design services, creating conditions for the smooth production of the project;

Secondly, during the implementation of the project, the company fully leveraged its experience and advantages in material balance and technical detail design, ensuring that the production line capacity met and exceeded the standard, and the product quality reached a higher level of project goals;

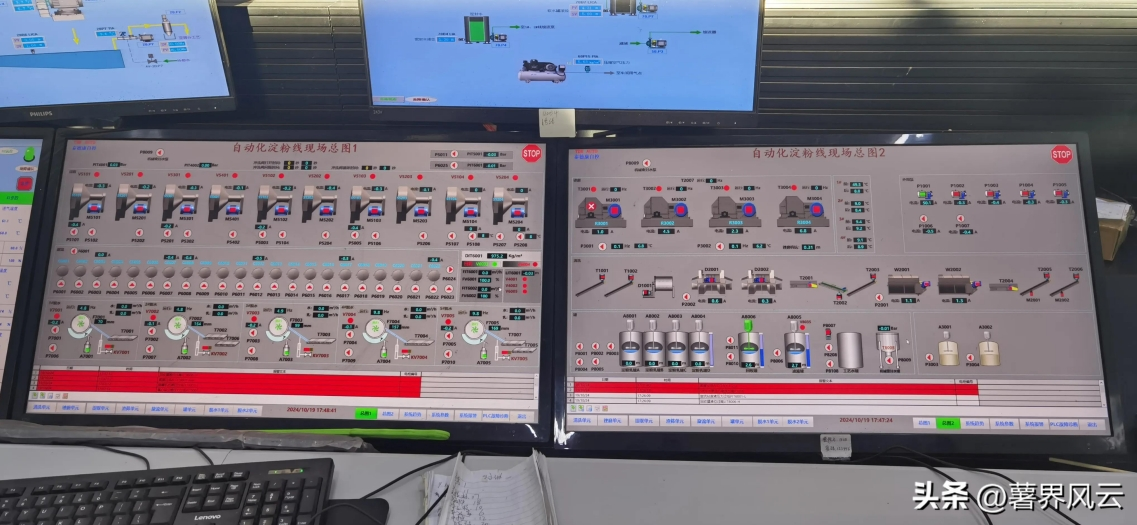

Thirdly, the entire production line adopts a fully automatic control system, which optimizes the number of control points and key points to ensure stable and continuous operation of the production line;

Fourthly, based on the raw material situation in the project location, the pre-treatment, cleaning, and stone removal section of the production line has been optimized, providing reliable guarantees for the improvement of product quality;

Fifthly, the extraction and refining process has been optimized to ensure stable and continuous operation of the production line. In addition, the professional project management team and project manager's dedication of Tidecom are also important conditions for ensuring the smooth implementation of the project.

Regarding the successful result of the one-time production of this revolutionary 100 ton/hour potato production line, Wang Zhengang, Chairman of Tianshanxue, said, "This is the most wonderful embodiment of Tianshanxue and Tidecom's two-way rush." Yan Ya, General Manager of Tidecom, said that the design and manufacturing of the 100 ton/hour production line have well integrated customers' ideas and experiences. At the same time, great attention is paid to details in the production and manufacturing stage, such as using high-end titanium steel for all steel, and using original parts from internationally renowned manufacturers such as Germany's Kron, GeMi, Siemens, and Tianshui 213 for instruments and electrical components.

In the central control room, Li Wei excitedly told me that Tianshanxue's self-control level is currently the highest in the industry. There are more than 4,000 control points on the 100 ton/hour potato production line, such as electrical monitoring, current pre monitoring, current code protection monitoring, etc. On the one hand, it effectively protects the stable operation of electrical components, and on the other hand, it also achieves energy-saving effects.

It is reported that Tianshanxue is a comprehensive enterprise that integrates basic agricultural planting, agricultural machinery investment services, potato starch industrial processing and comprehensive utilization of by-products, and supply chain services. We currently operate a 40,000 acre Voran Potato Farm on the northern foothills of the Tianshan Mountains in the Ili River Valley, which is the most mechanized and advanced high starch potato production base in China. This year, all the starch raw materials for Tianshanxue come from this farm, and we are gradually establishing GLOBAL G.A.P global good agricultural practices and a high standard agricultural model with full traceability.

Finally, Wang Zhengang stated that in 2024, Tianshanxue underwent a large-scale technological upgrade and has built the largest single unit intensive chemical plant in China. It has eight aerodynamic potato sorting lines, an automated potato starch production line with three lines in one, a daily sorting input of 5,000 tons of potato raw materials, a daily production of 800 tons of potato starch, an annual production capacity consumption of 300,000 tons of potatoes, and a yield of 50,000 tons of potato starch per season. Tianshanxue adheres to the core advantages of basic agriculture to drive the sustainable development of starch industry and build a model of potato starch intensive agriculture in China.